Article by Sarah Reddick – Photos by Newt Rayburn

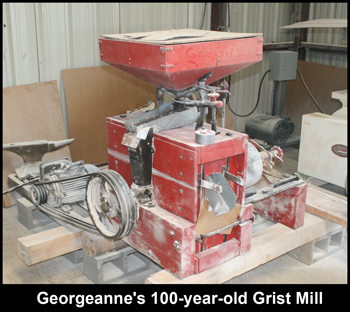

Georgeanne Ross was living with her husband Freddie in the Mississippi Delta in 2000 when she became a grit purveyor quite by accident. She’d suggested to her husband that they grind corn into cornmeal as a hobby. Freddie found an old grist mill, refurbished it, and taught Georgeanne about making cornmeal, something she enjoyed learning about because, as she put it, “I grew up in Memphis. If they didn’t sell it at Kroger, I didn’t think about it.”

Georgeanne Ross was living with her husband Freddie in the Mississippi Delta in 2000 when she became a grit purveyor quite by accident. She’d suggested to her husband that they grind corn into cornmeal as a hobby. Freddie found an old grist mill, refurbished it, and taught Georgeanne about making cornmeal, something she enjoyed learning about because, as she put it, “I grew up in Memphis. If they didn’t sell it at Kroger, I didn’t think about it.”

They would grind 20 pounds of corn once in a while in order to keep their machinery oiled and working properly, and then they would give the cornmeal away to neighbors. One day a Memphis chef was fishing near them and Georgeanne gave him some of the cornmeal. He called later and asked her for 40 pounds of grits. “I had to tell him, hey, I’m not in the business,” Georgeanne laughed, not knowing this conversation would set off a chain of events that would firmly place her in the grit business.

They would grind 20 pounds of corn once in a while in order to keep their machinery oiled and working properly, and then they would give the cornmeal away to neighbors. One day a Memphis chef was fishing near them and Georgeanne gave him some of the cornmeal. He called later and asked her for 40 pounds of grits. “I had to tell him, hey, I’m not in the business,” Georgeanne laughed, not knowing this conversation would set off a chain of events that would firmly place her in the grit business.

Georgeanne discovered that the grist mill could produce several products. When the corn is finely ground it produces corn meal, masa, polenta is a little less fine, and then it also produces grits. In traditional Italian dishes, polenta is turned into a cake similar to hoe cakes made from grits, and the polenta cakes can be served covered in marinara. She also decided to stone grind pure yellow, cracked corn. “People were used to white grits, but I decided I would sell mine by telling people they look like melted butter when they’re cooked.” She buys the corn from a Mississippi farm, but further details are a trade secret.

Georgeanne discovered that the grist mill could produce several products. When the corn is finely ground it produces corn meal, masa, polenta is a little less fine, and then it also produces grits. In traditional Italian dishes, polenta is turned into a cake similar to hoe cakes made from grits, and the polenta cakes can be served covered in marinara. She also decided to stone grind pure yellow, cracked corn. “People were used to white grits, but I decided I would sell mine by telling people they look like melted butter when they’re cooked.” She buys the corn from a Mississippi farm, but further details are a trade secret.

The chef in Memphis advised Georgeanne to start approaching owners of “white tablecloth restaurants” to ask them if they were interested in using her grits, because people were starting to revert to using products that were all natural, without additives and preservatives. So, Georgeanne began driving to area restaurants and peeking in the windows, looking for white tablecloths. She started out by leaving them a five pound sample bag and then checking back with them later. “I have never advertised,” she said, “It’s all been by word of mouth.” One of her biggest clients in the North Mississippi area is John Currence. City Grocery uses her grits for their signature shrimp and grits dish, and Big Bad Breakfast recently incorporated her grits into a meal named for The Local Voice, which also includes pork chops from Old Thyme Farms and bread from Bottletree Bakery.

The chef in Memphis advised Georgeanne to start approaching owners of “white tablecloth restaurants” to ask them if they were interested in using her grits, because people were starting to revert to using products that were all natural, without additives and preservatives. So, Georgeanne began driving to area restaurants and peeking in the windows, looking for white tablecloths. She started out by leaving them a five pound sample bag and then checking back with them later. “I have never advertised,” she said, “It’s all been by word of mouth.” One of her biggest clients in the North Mississippi area is John Currence. City Grocery uses her grits for their signature shrimp and grits dish, and Big Bad Breakfast recently incorporated her grits into a meal named for The Local Voice, which also includes pork chops from Old Thyme Farms and bread from Bottletree Bakery.

Georgeanne says the piece of equipment she could not live without is her grit separator. The separator allows the grits to travel through a pipe from the grist mill where it is sifted through several screens to filter out the flour before being divided into categories by texture. The separator can produce upwards of 600 pounds per hour. She said when they first started they would hand sift everything on screens, and that a few pounds of grits could take hours to produce. Given that Georgeanne recently began doing private milling for a company on the east coast that has a standing order for 500 pounds a month, the separator is indeed a vital part of the process. She described a typical work day as, “Busy, and dusty.”

Georgeanne says the piece of equipment she could not live without is her grit separator. The separator allows the grits to travel through a pipe from the grist mill where it is sifted through several screens to filter out the flour before being divided into categories by texture. The separator can produce upwards of 600 pounds per hour. She said when they first started they would hand sift everything on screens, and that a few pounds of grits could take hours to produce. Given that Georgeanne recently began doing private milling for a company on the east coast that has a standing order for 500 pounds a month, the separator is indeed a vital part of the process. She described a typical work day as, “Busy, and dusty.”

As she stood looking around at the beautiful farmland her business is located on, Georgeanne said, “You know, Americans consume about 100 million pounds of grits every year.” She then talked for a bit about farmers’ markets and how she hopes that more and more people turn to purchasing foods grown and produced locally. When asked what she is most proud of this year so far she said, “My hubby beating cancer.” When asked what she’s most looking forward to, she smiled and said, “A vacation.”

You can contact Georgeanne Ross via her website: www.gritgirl.net